Note: no Lockheed Martin  proprietary

data is shown here.

proprietary

data is shown here.

OVERVIEW

The Atlas V is Lockheed's design for the USAF's EELV (Evolved Expendable Launch Vehicle) program. Boeing is also participating with their Delta IV, which will ultimately compete against the Atlas V in the commercial launch market. (The EELV program has carried both designs into production.) The standard Atlas V variant has about 860,200 lbs of lifting power (thrust) at sea level take-off, thanks to it's NPO EnergoMash RD-180 engine (1) (2) (3) (4), while the heavy-lift variant has about 2.5M lbs.

The RD-180 production line will be managed by RD AmRoss LLC, a joint-venture of NPO EnergoMash and Pratt & Whitney Space Propulsion, set up after technology safeguard agreements between the U.S. and Russia, to protect Russian technologies and prevent proliferation, were finalized. NPO Energomash will receive a licensing fee for each engine produced in the U.S., which as of this writing is expected to start no earlier than 2005.

The Atlas V family is capable of lifting payloads up to 19,100 lb (8,650 kg) to geosynchronous transfer orbit (GTO).

Atlas V "552" configuration in AEDC wind tunnel.

RECENT STUFF

July 2003: HUGE EELV INDUSTRIAL ESPIONAGE SCANDAL AT BOEING!! LOCKHEED MARTIN WINS!!

August 2002: Inaugural launch.

|

article, Aviation Week & Space Technology, 8-26-2002 issue article, Aviation Week & Space Technology, 9-16-2002 issue press release, Lockheed Martin, 8-21-2002 article, www.SpaceflightNow.com, 8-22-2002

|

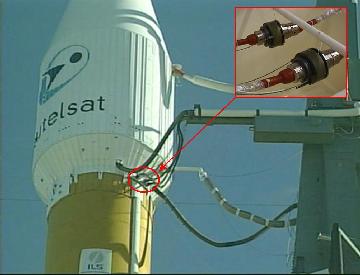

DEVELOPMENT HISTORY, COMMON CORE BOOSTER UMBILICAL CONNECTOR

Atlas V launch location at Cape Canaveral Air Station, FL |

what it's launch complex will look like (Complex 41, Cape Canaveral Air Station, FL) |

First, clear Complex 41 from Titan IV use... |

...then build the new Atlas V complex. |

|

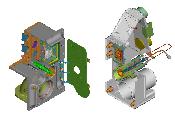

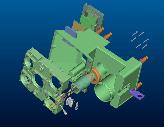

Atlas V exploded views |

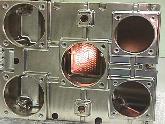

Common Core Booster (CCB) umbilical connector plug & receptacle [recent design] |

mated pair (the gold receptacle flies away with the rocket) [early design] |

Proof Of Concept CCB prototype (interface region only), plug & receptacle |

|

Proof Of Concept CCB prototype, plug |

Proof Of Concept CCB prototype, receptacle |

Proof Of Concept CCB prototype, receptacle hinge detail |

Proof Of Concept CCB prototype, flapper door latch detail (open) |

|

Proof Of Concept CCB prototype, flapper door latch detail (locked) |

Full-Up Prototype CCB design (plug only shown; housing milled, not cast) |

Full-Up Prototype CCB |

Full-Up Prototype CCB |

|

Full-Up Prototype CCB, plug detail |

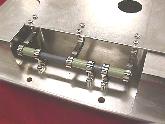

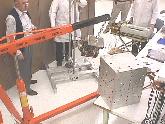

Full-Up Prototype CCB, static pulls test setup (note large solid magnesium vibration fixture [cube]) |

Full-Up Prototype CCB, me doing a mate |

Full-Up Prototype CCB, static pulls testing |

Full-Up Prototype CCB, static pulls testing |

Full-Up Prototype CCB, dynamic (vibration) test setup |

Full-Up Prototype CCB, dynamic (vibration) test to failure |

Full-Up Prototype CCB, dynamic (vibration) test to failure |

CCB Qualification & Production units' housings in work, plug (cast) |

CCB Qualification & Production units' housings in work, plug (post-cast machining) |

MONTHS LATER: boot the casting vendor and go with massively simplified milled housings. |

Engineering Test Unit build (~333 signals) |

|

Engineering Test Unit build: bad hair day |

Engineering Test Unit build: disemboweled |

Engineering Test Unit build |

Engineering Test Unit build |

|

Engineering Test Unit build: 10# of something into a 5# box |

Engineering Test Unit build |

Engineering Test Unit electrical testing: buzzing out lines |

Engineering Test Unit electrical testing: more buzzing out lines |

the first CCB flight vehicle in final assembly in Denver, April 2001 |

CCB rollout ceremony, April 2001. Speaker: Darleen A. Druyun, principal deputy assistant secretary of the Air Force for acquisition and management (EELV is an Air Force program) |

CCB packed up for shipment to the Cape, May 2001 |

Antonov 124 unloads CCB at the Cape, May 2001 |

our beefed-up redesign on one of the Qual Units, pre-assembly; from "bad hair day" to Medusa. |

CCB EMI Qualification Testing, February/March 2002 |

CCB Vibration Qualification Testing, February/March 2002 |

RD-180 Throttle-up vibration simulation in 1 axis, up to demate (MPEG4 Video, 5.6 MB) |

March 2002: First roll-out for WDR (Wet Dress Rehearsal), where the bird is tanked and ground ops are ran as would be done for flight (up to launch without lighting the match). Tank RP-1, then tank the Cryos... verify all ground to airborne interfaces, procedures, hardware and software. After WDR comes Sim-flight which carries the testing forward, faking out the Avionics, making the bird think it's flying. |

Atlas V heritage

|

||

|

inaugural launch video, CCB connector in action (AVI video, 3.0 MB) |

REF: inaugural launch video, Centaur connector in action -- plus rocket fly-by! (AVI video, 3.3 MB) The Centaur connector was developed at the same time as the CCB connector. There are 3-5 of them per vehicle. |

||

|

Atlas V promo poster |

Atlas V Payload Planner's Guide (1.4 MB, Adobe Acrobat PDF format) |

and for reference, just so you can see how big the Atlas V is fully assembled... |

|

Report dead links to the webmaster.

This page was last updated on 10/10/14 .